什么是導電膠

時間:2018-01-30

作者:儀(yi)表網

閱讀:5401

近年來(lai),電(dian)子(zi)元器(qi)件的(de)(de)小(xiao)型(xi�������ng)化(hua)、微型(xing)化(hua),印刷電(dian)路(lu)板(ban)的(de)(de)高密化(hua)�����、集成化(hua)這(zhe)一工(gong)業(ye)化(hua)趨勢,催生了導電(dian)膠(jiao)這(zhe)一新興膠(jiao)黏材(cai)料的(de)(de)興起(qi)。

導(dao)電(dian)(dian)(dian)(dian)膠一(yi)般(ban)由(you)基(ji)體(ti)樹脂、導(dao)電(dian)(dian)(dian)(dian)填(tian)料(金屬粉末為(wei)主)、稀釋劑、交聯劑、催化劑和其他添(tian)加劑組成,是一(yi)種固(gu)化或干燥(zao)后具有(you)一(yi)定導(dao)電(dian)(dian)(dian)(dian)性(xing)(xing)能(neng)和粘結性(xing)(xing)能(neng)的(de)膠黏(nian)劑。其導(dao)電(dian)(dian)(dian)(dian)機理是通(tong)過基(ji)體(ti)樹脂的(de)粘接(jie)作(zuo)用(yong)把導(dao)電(dian)(dian)(dian)(dian)粒子結合在一(yi)起,形成導(dao)電(dian)(dian)(dian)(dian)通(tong)路,實現被粘材料的(de)導(dao)電(dian)(dian)(dian)(dian)連接(jie)。相比傳�������(chuan)統焊(han)接(jie),導(dao)電(dian)(dian)(dian)(dian)膠具有(you)工藝簡單(dan)環保(bao)、低溫固(gu)化等特點,應用(yong)潛力巨大。

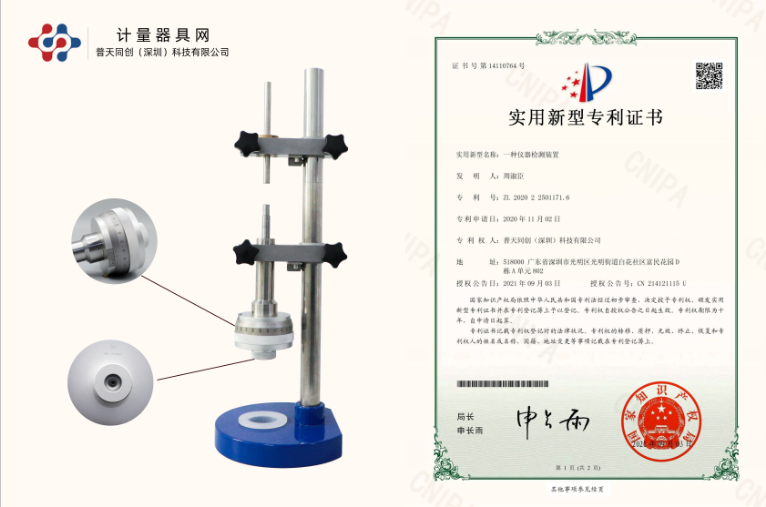

然而導(dao)(dao)電膠(jiao)(jiao)在目前的應(ying)用中仍存在一些缺陷,如電導(dao)(dao)率較(jiao)(jiao)(jiao)低(di),工作時會產生較(jiao)(jiao)(jiao)高的電阻熱,導(dao)(dao)電性能較(jiao)(jiao)(jiao)差,耐碰(peng)撞(zhuang)沖(chong)擊能力較(jiao)(jiao)(jiao)差,尤其是在溫度(du)、濕(shi)度(du)等(deng)環境應(ying)力下粘(z�����han)(zhan)結強(qiang)度(du)較(jiao)(jiao)(jiao)低(di)。這(zhe)是由于(yu)粘(zhan)(zhan)接界面氧化腐蝕、裂(lie)縫(feng)分層,導(dao)(dao)電膠(jiao)(jiao)蠕變等(deng)因(yin)素共同導(dao)(dao)致的,而這(zhe)將對導(dao)(dao)電膠(jiao)(jiao)的日常應(ying)用帶來(lai)極大的安全威脅。因(yin)此,將導(dao)(dao)電膠(jiao)(jiao)粘(zhan)(zhan)結強(qiang)度(du)的性能管控納入(ru)企業(ye)質(zhi)量(liang)監管顯(xian)得尤為重要(yao)。